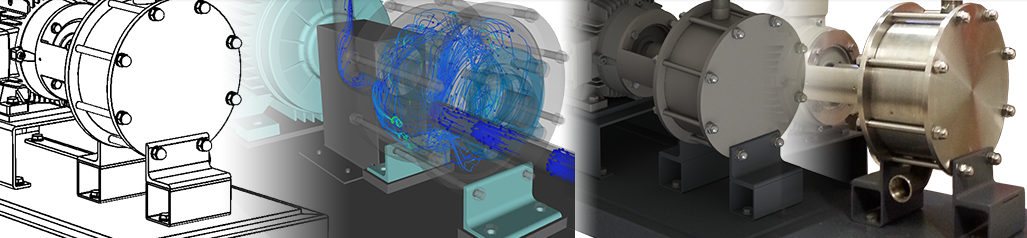

CaviMax - Hydrodynamic Cavitation Technology

Not just for BIOGAS PLANTS. You may already be in the know with regards to the power of controlled cavitation and how it can help your particular industry or physical/chemical/biological/nano process, if not then follow these 4 steps...

-

Step 1:- do a web search with the words Hydrodynamic Cavitation plus the name of what you are doing i.e.. waste water treatment, beer making, upscaling algae into biofuels/algal oils/bioethanol, biodiesel production from biowastes , bioresource processing, oil desulphurisation, gene therapy targeting, desalination, yogurt processing, paint mixing or COD reduction or whatever you want to do

-

Step 2:- get excited about Hydrodynamic Cavitation and what it can do for you because there are so many papers out there with favorable to outstanding results

-

Step 3:- contact us to discuss the hire of our laboratory scale CaviLab to test your hypothesis for your particular situation and aims, do some R&D - our favorite

-

Step 4:- if you achieve the results you are looking for, and are suitably impressed by the process uplift achieved then proceed to scaled up industrial sized cavitator

NB:- please note the CaviMax produces Hydrodynamic Cavitation not Acoustic Cavitation - both are viable cavitation bubble technologies but Hydrodynamic Cavitation is more efficient when scaled up, producing more powerful shockwaves with less energy input - this is a process intensification technology which increases/intensifies/speeds up the rate of reactions leading to decreased energy and raw materials usage and targeted manipulating of chemicals.

Thanks for reading, share this info and when you are in a position to evaluate new technologies and techniques that will provide substantial carbon savings and increased profit, then please get in touch, we love running cost benefit analyses to show how you can save money and provide environmental benefit (through either using less materials, cleaning up your effluent or both) at the same time - please include Hydrodynamic Cavitation in your innovative technology evaluations.

We are based in Dorset in the United Kingdom but are happy to serve the world.

Use hydrodynamic cavitation to reduce particle sizes and break down lignocellulosic feedstocks, recalcitrant substrates and secondary sludges

We have a proven technology to distrupt the lignin in straw and grass, which we know is the key to utilising these plentiful and lower cost feedstocks. There are a couple of existing processes capable of doing this, such as steam and alkali treatment. However, we have an innovative and clever machine that harnesses the power of hydrodynamic cavitation.

The  Rotocav reactor at the heart of the CaviMax makes all this possible by producing physical rotational forces that create hydrodynamic shockwaves, breaking down seemingly incompatible gas/liquid/solid mixtures into flowing substrates.

Rotocav reactor at the heart of the CaviMax makes all this possible by producing physical rotational forces that create hydrodynamic shockwaves, breaking down seemingly incompatible gas/liquid/solid mixtures into flowing substrates.

The shockwaves induced by a liquid moving from a high to low to high pressure environment, causes millions of microscopic bubbles to form and then collapse, creating tremendous localised pressures, which shear solid particles, break down cell walls and allow liquids to bind with solids, or gases to liquids. For the biogas industry this means that a substrate is created with a greater surface area, which is more readily available to be broken down by the anaerobic digestion bacteria, this in turn means more biogas...quicker.

So, in short theCaviMax cavitator is a process intensification device which increases sustainability ratings, lowers carbon footprints, provides flexibility in the running of your plant and can increase your biogas yield.

Below is a list of features and benefits of cavitation for the biogas industry, this isn't just a load of sales flannel, these are real and quantifiable effects, put us to the test, we have a laboratory scale cavitator we can test your particular troublesome substrate or a new feedstock you have in mind.

Why the emphasis on CONTROLLED hydrodynamic cavitation? Because generally cavitation is a plumbing and flow dynamics problem you try and engineer out of a system, as it can wear away pipework and parts within a water system, we are manipulating and controlling the cavitation event to discharge it's distruptive energy into a flowing medium and using it for particle disintegration.

Features of CONTROLLED hydrodynamic cavitation

Process intensification technology

Breaks down / digests lignocellulose

Deals with recalcitrant materials

Drasticly reduces particle size of treated substrate

Multiple treatment positioning, feedstock pre-treatment or mid process

Low maintenance simple design

No additional chemicals or add-ons required

A range of sizes available to suit your plant and requirements.

Environmentally friendly, efficient and economical in its application

Benefits of CONTROLLED hydrodynamic cavitation

Reduce feedstock costs or increase biogas production by on average 20%

Ability to utilise high lignin feed stocks

Broadens your feedstock portfolio

Decreased problematic floating layer – crust reduction in digester

Increased availability of cellular juices

Increased uniformity of particle size

Acceleration of hydrolysis and the anaerobic digestion process

Reduced retention time in digester

Increased pumpability of substrate

Reduction in digestate viscosity

Reduced plant downtime due to blockages

Increased sustainability of process & product by improved efficiencies