CaviMax is the machine; controlled hydrodynamic cavitation is the means to maximising the potential of your biogas plant. By installing one in your plant you could increase your biogas yield by up to 20% (we've achieved biomethane uplifts of between 10% and 56% depending on the positioning of the machine and the substrates and feedstocks) and utilise previously unusable feedstocks.

Finally unlock the energy potential of straw, grass and high lignin feedstocks, secondary sewage sludges, food waste streams, treat recalcitrant materials and troubleshoot problem floating layers.

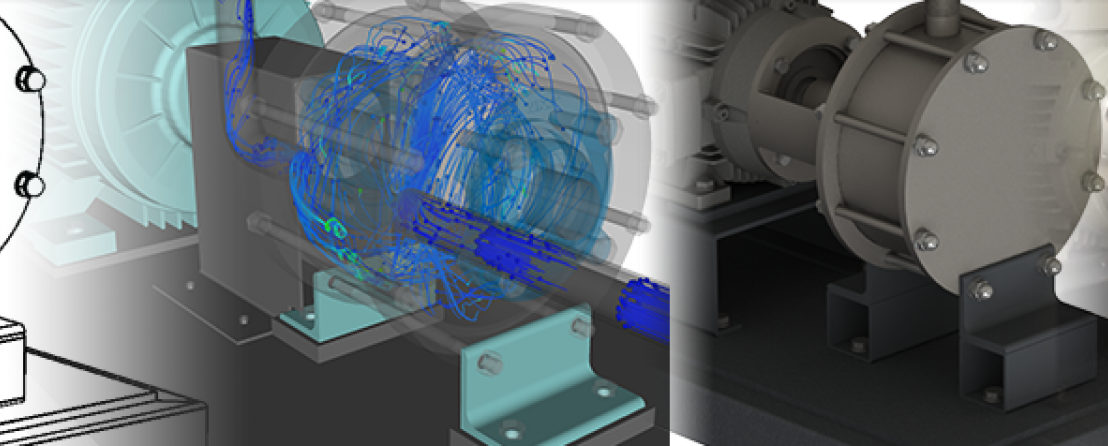

This is a plug & play inline process intensification device – no additional chemicals needed, install and away you go.

THE machine for decarbonisation / sustainability / circular economies / pollution control / process intensification

As we say....Get more bang for your buck...fit a CaviMax

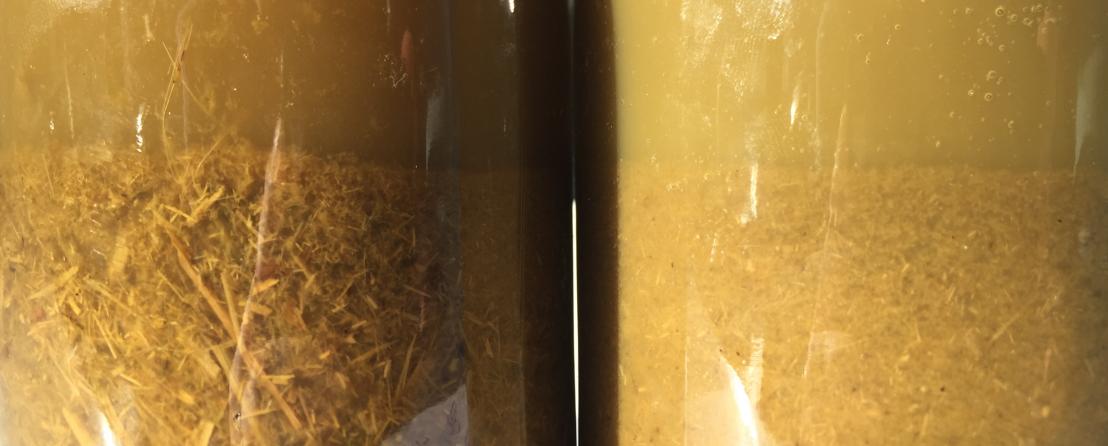

This photo shows uncavitated material on the left and cavitated material on the right, as can be seen particle sizes are drasically reduced.